AI And Data Management: Revolutionizing Industrial Transformation In 2025

Heavy asset industries are under increasing pressure to improve operational efficiency and safety while navigating complex challenges. In response, firms are turning to cutting-edge technologies, such as AI, and robust data management practices. These tools are central to efforts to streamline process safety management (PSM), improve asset performance and foster innovation. Insights from the 2025 Verdantix industrial transformation global corporate survey reveal that AI, particularly generative AI (GenAI), is playing a transformative role in industrial operations. From automating tasks to addressing intricate challenges, firms are rapidly adopting AI-driven solutions to enhance efficiency. Specifically, the research findings reveal that:

- AI-based analytics is a major driver of industrial transformation.

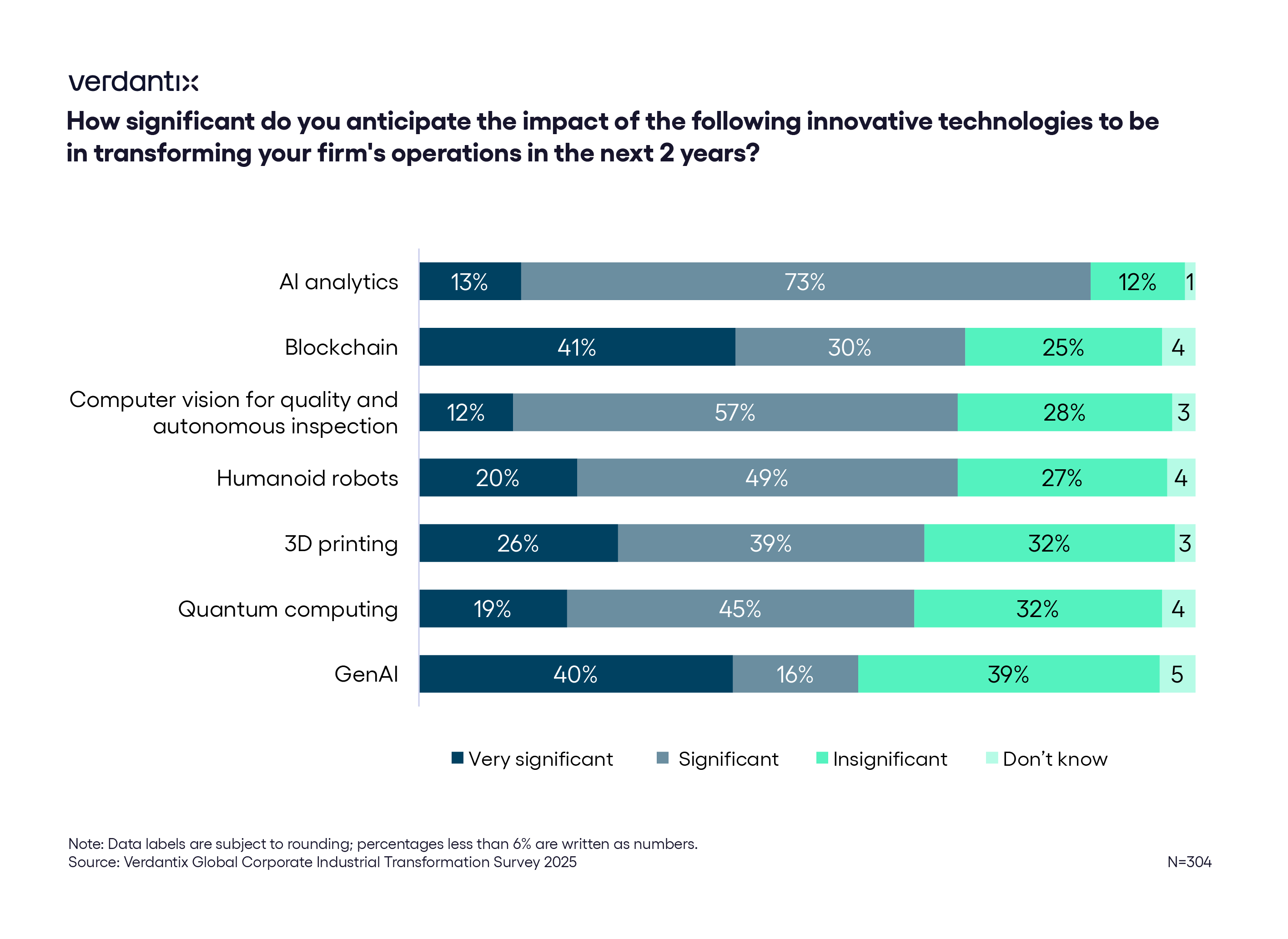

AI analytics is set to play a significant role in transforming industrial operations by enabling improved efficiency and quality, as well as data-driven decision-making. Firms are leveraging advanced machine learning models and real-time data insights to optimize processes, reduce waste and enhance operational strategies. The survey highlights the transformative potential of AI, with 87% of respondents predicting that AI-based analytics will significantly transform their operations over the next two years.

- Automated issue prioritization is the top AI use case.

Automated issue prioritization emerged as the most valuable use case for AI, with 58% of respondents ranking it as their top choice. Industrial environments often produce overwhelming amounts of data that can hinder timely decision-making. AI addresses this challenge by simplifying the decision-making process for plant managers, helping them cut through information overload. By automating routine tasks and highlighting critical issues, AI enables managers to focus on what truly matters, significantly improving operational efficiency and outcomes.

- GenAI is transforming operational efficiency.

GenAI is expected to play a pivotal role, with 40% of respondents rating its impact as “very significant”. In fact, 65% of the 304 respondents to the survey stated that they have already implemented, are currently implementing or are actively exploring the use of GenAI in their plant operations. For example, Cereal Partners Worldwide, a joint venture between Nestlé and General Mills, introduced GenAI assistant Max within their consumer market insights and analytics teams. Max enables real-time analytics, generates actionable insights and streamlines decision-making processes.

- Poor data quality remains a significant challenge.

Data quality is a “significant” or “very significant" barrier to achieving successful industrial AI analytics projects for 75% of firms. A major contributor to poor data quality is the lack of integrated operational technology (OT), information technology (IT) and engineering technology (ET) systems. The survey reveals that only 6% of organizations have achieved full data integration, underscoring the need for investment in robust data infrastructure. To overcome data quality and data integration challenges, firms can adopt industrial data management platforms offered by providers such as ABB, AVEVA, Cognite and HighByte, which are specifically designed to address data quality issues and enable seamless integration.

The adoption of AI – particularly GenAI – is revolutionizing industrial operations, enabling firms to improve efficiency, enhance safety and streamline decision-making. However, achieving these benefits requires robust data integration and awareness of AI solution providers. By addressing these challenges, organizations can unlock the full potential of AI and position themselves for long-term success in an increasingly competitive industrial landscape.

About The Author

Josh Graessle

Senior Manager