Boeing Reunites With Spirit AeroSystems To Salvage Quality Management Control

Rain Chiang

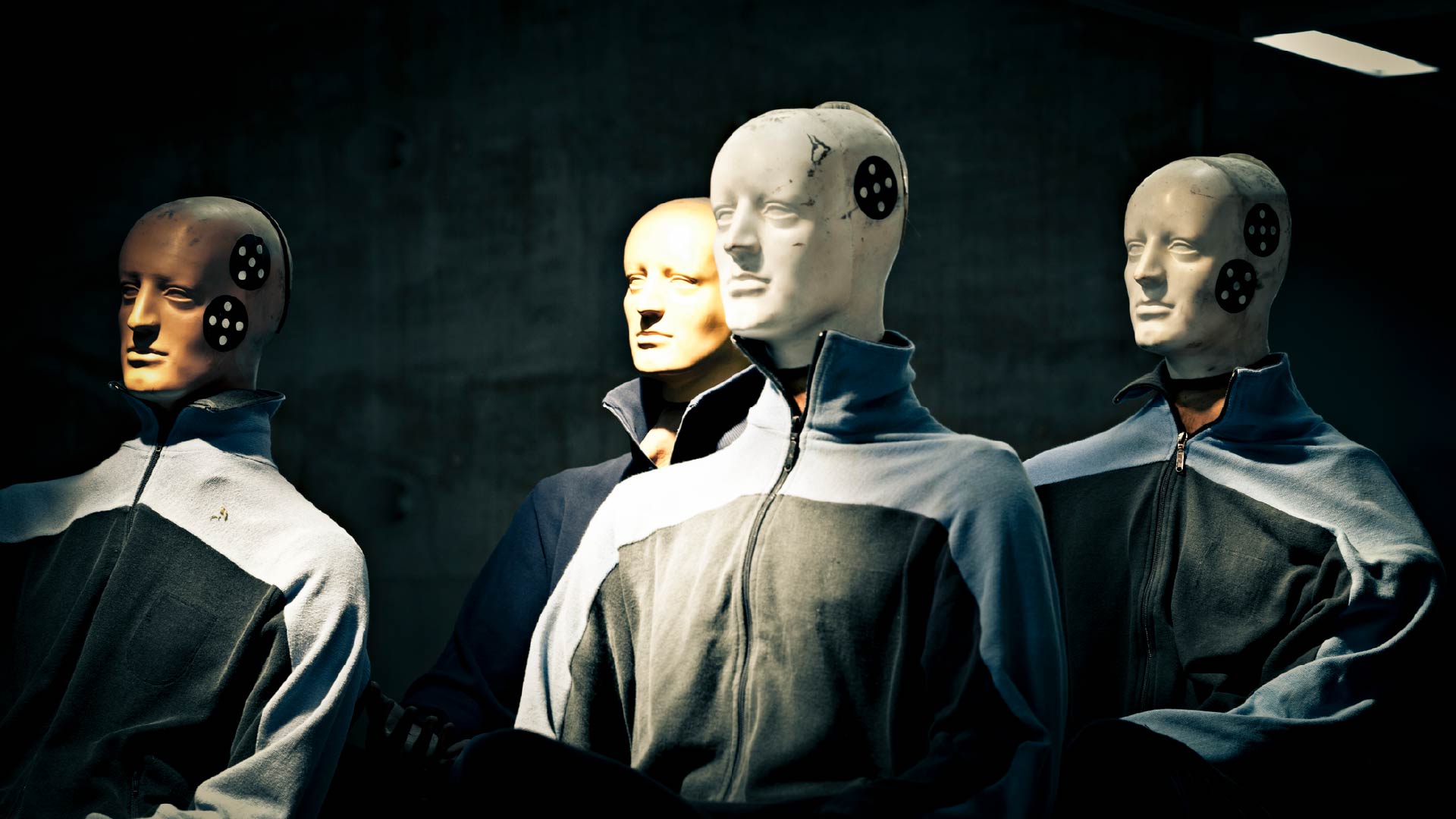

On June 30th, Boeing announced its all-stock acquisition of Kansas-based Spirit AeroSystems at $37.25 per share. The transaction values Spirit at $4.7 billion, breaking up the firm with some assets going to Airbus. The move follows Boeing’s current quality management crisis, which culminated in an unused door blowing out of a Boeing 737 Max model shortly after take-off during a commercial Alaska Airlines flight in January. This incident triggered close investigations into Boeing that revealed the door panel was missing four key bolts, which workers removed while repairing damaged rivets the year prior. The Federal Aviation Administration (FAA) failed 40% of Boeing’s audits over its manufacturing process for 737 Max commercial jets and found its critical manufacturing partner Spirit failing 54% of federal quality audits.

Spirit AeroSystems was part of Boeing until it split off in 2005. Boeing initially split from Spirit in efforts to reduce operational costs, further highlighting practices that may jeopardize quality. Since then, Boeing has accounted for 70% of all orders from Spirit, while its competitor Airbus has accounted for 25%, stressing its continued dependency on critical services. Today, Spirit has grown to be the largest Tier 1 manufacturer and supplier of aerostructures, with 14,800 employees. The manufacturer has a total debt of $3.9 billion, which brings up the true value of the Boeing transaction to $8.3 billion – underlining Boeing’s determination to regain control over its manufacturing quality management. This deal signifies the firm’s shifting approach away from outsourcing critical component manufacturing. Boeing CEO David Calhoun stated that this move would enable the firm to “align [its] commercial production systems, including [its] safety and quality management systems”.

The aerospace industry already experiences high regulatory scrutiny over quality management due to its systems' complexity and the product’s direct influence over public health and safety. The Boeing incident is an emblematic case of the comprehensive risks of failing to integrate quality management systems into operations, which is significantly magnified as organizations scale to manage global supply chains. David Calhoun will be stepping down as CEO by the end of 2024 – with this announcement coming less than three months after the January incident. The FAA also imposed a cap on the production of Boeing’s best-selling plane. Boeing stock has fallen 25% since the January 5th crash. These factors coincide with Boeing’s deteriorating public perception, calling for closer integrations between quality management, procurement and manufacturing teams across suppliers. An expert panel reviewing Boeing's safety management processes found a "disconnect" between its senior management and employees regarding safety culture, amongst other concerns.

The Boeing case study highlights the close relationship between safety and quality outcomes. Sustainable workforce practices lead to improved productivity and consistent product quality, while high-quality processes mitigate worker risks and ensure product safety. Quality management practices necessitate continuous improvement efforts as the ultimate responsibility over quality disasters falls onto the vendor – Boeing – which must responsibly oversee its third-party suppliers. Furthermore, successfully fostering a safety culture requires firms to move from a punitive system to one where workers can raise quality or safety concerns without fear of repercussions.

To learn more, please read our report on the business case for integrating quality into operations. To see other EHSQ reports, visit our research portal.

About The Author

Rain Chiang

Industry Analyst