Industrial Facility Digital Twins: Tangible Benefits And Technology Maturity Fuels Uptake, Drives Supplier Go-To-Market Strategies

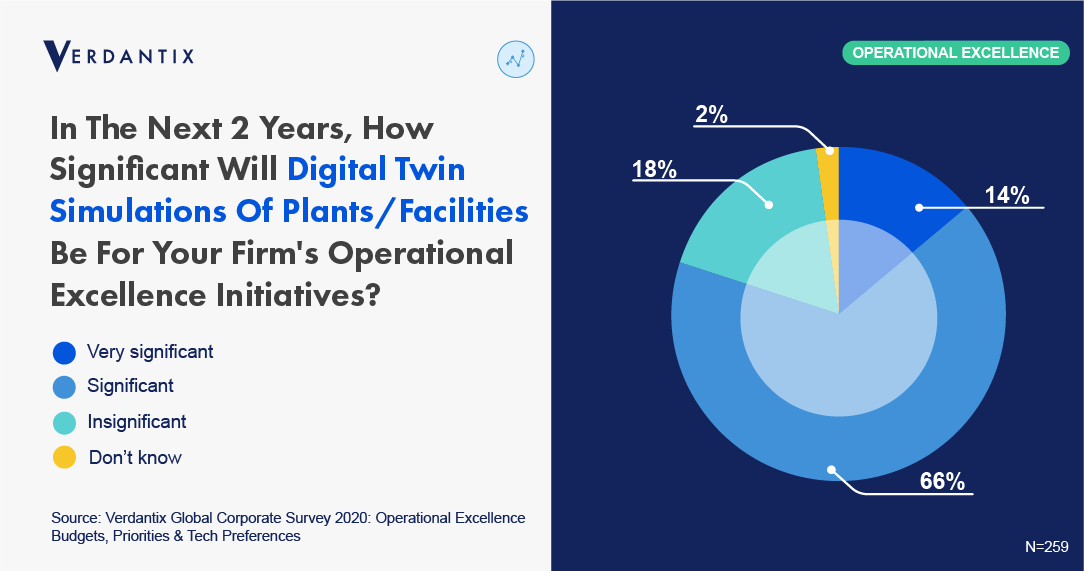

According to the 2020 Verdantix global corporate survey, digital twin simulations of industrial plants were mentioned as a ‘very significant’ or ‘significant’ digital innovation by 80% of the 259 executives in operations, maintenance, engineering and process safety roles for their firms over the next two years. Digital twin technology is steadily crossing the chasm and the market is undergoing fast growth with spending forecasted to reach nearly $3 billion in 2026 from $1 billion in 2021.

Digital twins deliver added value across the project lifecycle – from feasibility and conceptual design phase to operate and maintain and decommissioning phase. Advanced analytics, machine learning and physics-based simulations help with accurate budgeting, validation of process designs, improved inventory management, supply chain optimization and efficient handover from EPCs to owner-operators for capital projects. During the operate and maintain phase, digital twins help to enhance asset safety and performance by unlocking dark data problems as well as filling the gaps in asset information with virtual sensors. Rising sustainability concerns and risks can be mitigated by using what-if simulations to ensure production is maximized while staying within emission limits and understand the impact of environment-friendly material substitutes.

Industrial facility digital twins are not a standalone product category and consist of a broad swathe of functionalities, which include visualizations, data management, analytics and simulations. This means that there are only a handful of vendors that offer solutions with breadth of functionality covering these four areas such as ABB, Altair, AVEVA, Bentley Systems and GE Digital. The majority of suppliers offer point solutions such as Interaptix, with its AptixAR platform to create digital replicas of assets, Ansys with its simulation models and Senseye offering analytics for predict asset failure. However, given the strong growth in this market and to offer customers a holistic solution, vendors are enhancing their digital twin offerings via partnerships and acquisitions.

For more information on industrial facility digital twins technology, supplier landscape and how to start or continue your firm’s digital twin journey, read the Verdantix report Smart Innovators: Digital Twins For Industrial Facilities.

About The Author

Malavika Tohani

Research Director