What Happens When Industrial Experience Walks Out The Door

Labour and skills shortages have shifted from a cyclical concern to a structural constraint for industrial firms globally. Across manufacturing, energy, utilities and process industries, execution capability is increasingly limited not by capital or technology availability, but by access to skilled labour at scale. In 2026, workforce constraints are emerging as one of the most material forces shaping industrial agility strategies.

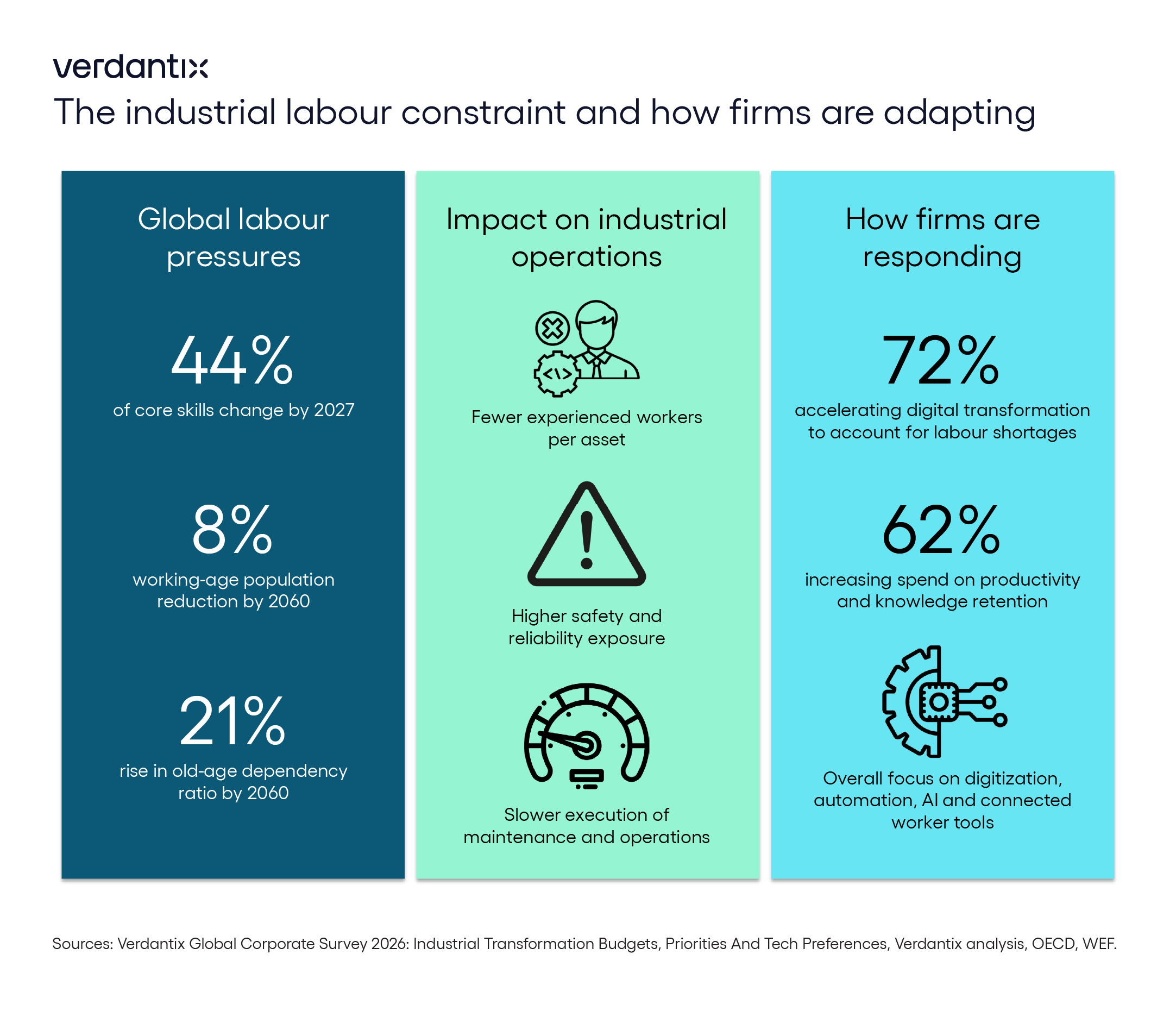

Global labour data highlight the scale and persistence of the challenge:

- The World Economic Forum reports that 44% of workers’ core skills are expected to change by 2027, driven by automation, AI and digitization, with manufacturing and other asset-intensive sectors among the most exposed.

- According to the OECD Employment Outlook 2025, the working-age population across OECD countries is projected to decline by 8% by 2060, while the old-age dependency ratio will rise from 31% in 2023 to 52% by 2060, increasing attrition risk in skilled trades and technical roles.

- Data from the US Bureau of Labor Statistics show that manufacturing job openings remain structurally elevated, with hundreds of thousands of unfilled roles across production, maintenance and technical occupations, despite softening macroeconomic conditions.

Taken together, these indicators point to a sustained mismatch between labour supply and industrial operating requirements, rather than a short-term hiring cycle.

Verdantix survey data show that these labour dynamics are directly influencing industrial investment priorities. Over 70% of firms identify the lack of skilled workers due to an aging and retiring workforce as a significant driver of digital transformation in plant operations. At the same time, more than 60% of organizations expect to increase spending on workforce productivity and knowledge retention initiatives over the next 12 months. This reflects a shift away from short-term hiring responses toward longer-term structural mitigation strategies (see below).

The challenge extends beyond headcount alone. Safety and regulatory pressures are compounding workforce constraints. Regulatory bodies such as OSHA continue to highlight elevated safety risks linked to fatigue, insufficient training and task overload in asset-intensive environments, drawing on insights from severe injury reporting and inspection activity. As experienced workers retire and staffing levels tighten, fewer personnel are increasingly responsible for managing complex assets, compliance obligations and production targets simultaneously.

To tackle these converging pressures, organizations are reframing labour shortages through the lens of industrial agility. Rather than relying solely on workforce expansion, leading firms are accelerating investments in automation, AI-enabled decision support and digital workflows to reduce dependency on scarce expertise. Predictive maintenance, remote operations, advanced process control and connected worker platforms are being deployed to standardize execution, capture tribal knowledge and extend the impact of experienced personnel across multiple sites.

This shift is reflected in broader transformation priorities. Verdantix data show continued investment momentum behind asset reliability, production optimization and workforce productivity initiatives. These areas sit at the intersection of labour constraints and rising performance expectations, where digital technologies can directly offset skills gaps while supporting safety, uptime and efficiency goals.

Looking ahead, labour and skills shortages are set to remain a defining feature of the industrial operating environment. Demographic trends, accelerating digital change and rising operational complexity make a return to pre-pandemic labour dynamics unlikely. In this context, industrial agility is no longer an efficiency ambition. It is a prerequisite for sustaining performance in a world where skilled labour is permanently constrained and where technology increasingly determines how much value each worker can safely and sustainably deliver.

To learn more, register for our upcoming webinar, The Industrial Skills Gap: Five Technologies Maintenance Teams Are Adopting In 2026, on February 18.

About The Author

Josh Graessle

Senior Manager