Four Considerations When Building A Business Case For Asset Maintenance Solutions

In today's competitive landscape, the proper maintenance and operation of industrial assets is crucial for operational efficiency, cost control, minimized downtime and optimized energy consumption. However, many firms still use paper and spreadsheets for asset maintenance management, leading to inefficiencies and unexpected failures.

As such, the market is witnessing a growing recognition of the importance of asset maintenance solutions. In the 2023 Verdantix operational excellence global survey, 55% of the operations, maintenance, engineering and process safety executives interviewed stated plans to increase investment in asset maintenance software to elevate operational efficiency, ensure compliance and optimize overall maintenance practices over the next 12 months.

Regardless of the growing need, industrial firms still struggle to quantify the benefits of asset maintenance solutions – and thus to convincing stakeholders and decision-makers to invest in such technology. In our business case report on asset maintenance solutions, Verdantix outlines a structured approach for operations managers and project leads to systematically build a persuasive business case for asset maintenance solutions. Some of the key steps are:

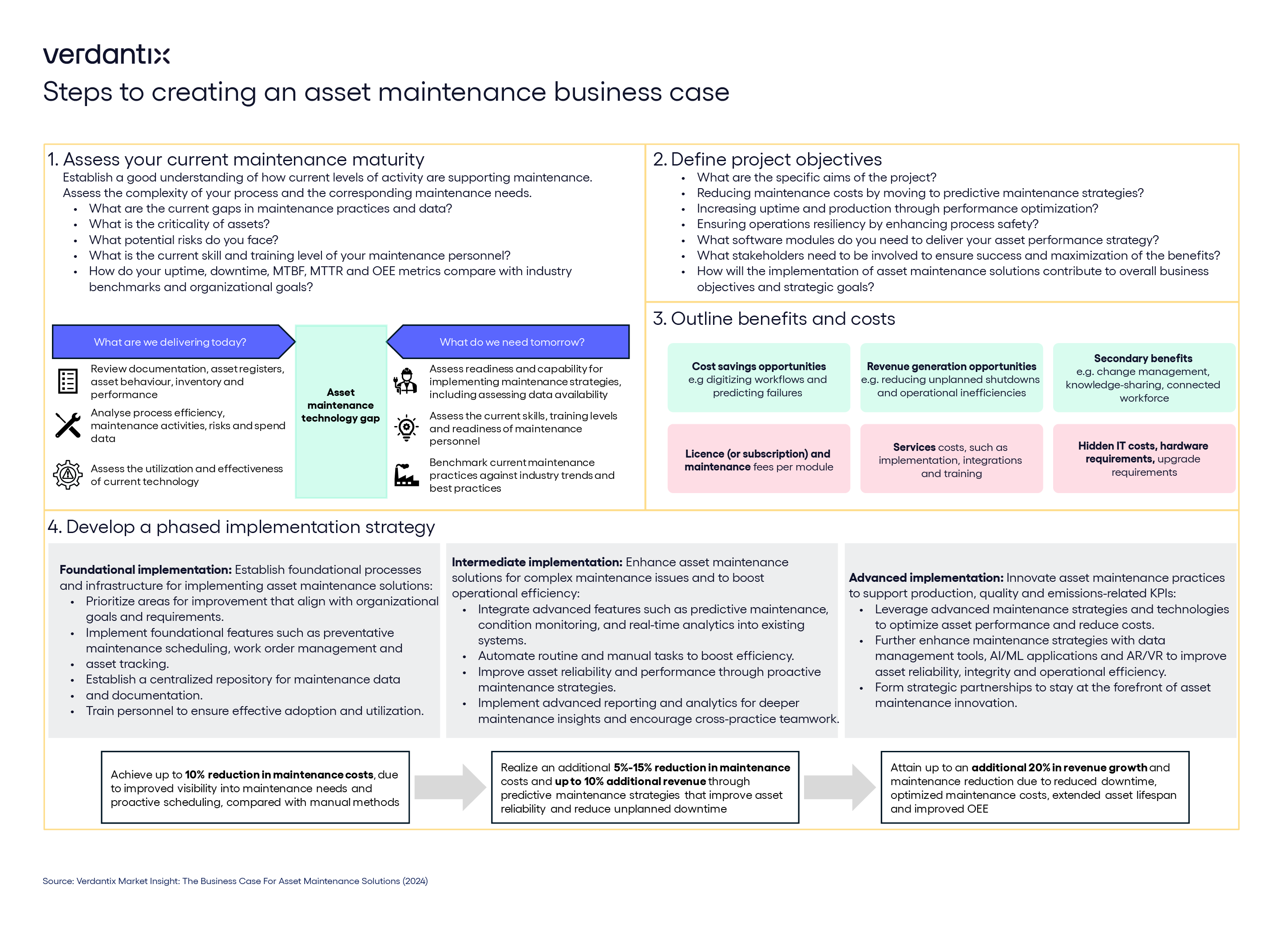

- Assess your current maintenance maturity.

Start by evaluating your organization’s current maintenance practices – identifying gaps and inefficiencies – while also assessing asset criticality, staff skill levels and performance against industry standards. This assessment will help you understand your firm’s current limitations, as well as technology gaps, and select asset maintenance strategies that align closely with future operational goals. Strategies are not one-size-fits-all, and can be reactive, preventative, condition-based, predictive, reliability-centred or risk-based maintenance. Whatever approach you decide to take, working with service providers such as Arcadis, Cohesive, MaxGrip and Wood for your firm’s asset maintenance digitization strategy and roadmap is a solid first step - Define project objectives.

Industrial facilities have turned to asset maintenance solutions for a plethora of reasons, ranging from reducing maintenance backlogs to production and energy optimization. Project leads must set clear, measurable objectives for their asset maintenance initiatives. These objectives must align with broader business goals, while implementation plans must maximize both operational efficiency and strategic impact. Additionally, firms should consider which software modules are necessary and identify the key stakeholders who should be involved in the project. - Outline benefits and costs.

Asset maintenance solutions offer value through cost savings and revenue generation opportunities. Project leads should quantify these benefits using historical data and typical outcomes, while also considering secondary advantages such as improved change management, knowledge sharing and workforce connectivity. Benefits should be framed in terms of ROI and alignment with strategic objectives. Regarding costs, project leads need to account for software licensing, implementation, integration, training services, hidden IT expenses like hardware requirements, and ongoing maintenance and upgrades. A balanced view of financial gains and expenditures is essential to present a clear value proposition for the project. - Develop a phased implementation strategy.

Asset maintenance deployments vary in complexity and therefore should be implemented in phases to ensure success and minimize disruption. Begin by focusing on foundational elements like preventative maintenance scheduling and staff training to build a solid base. Once these are in place, move to more advanced steps, incorporating features like predictive maintenance and automation to enhance asset reliability and efficiency. In the final phase, adopt cutting-edge technologies such as AI and machine learning to further optimize asset performance and facilitate scalability across other sites and assets. Each phase should deliver measurable improvements, such as cost reductions, enhanced asset uptime and greater operational efficiency.

When building a business case, project leads must not only demonstrate quantifiable cost savings but also show how the investment aligns with long-term strategic goals. This will create a compelling argument that positions asset maintenance software as a crucial investment for your organization’s future success.

To learn more about how to build a business case for asset maintenance solutions, please read our report, Business Case: Asset Maintenance Solutions, and follow our ongoing asset maintenance research by signing up to Verdantix Vantage.

About The Author

Kiran Darmasseelane

Senior Manager