Bad Data: AI's Worst Nightmare

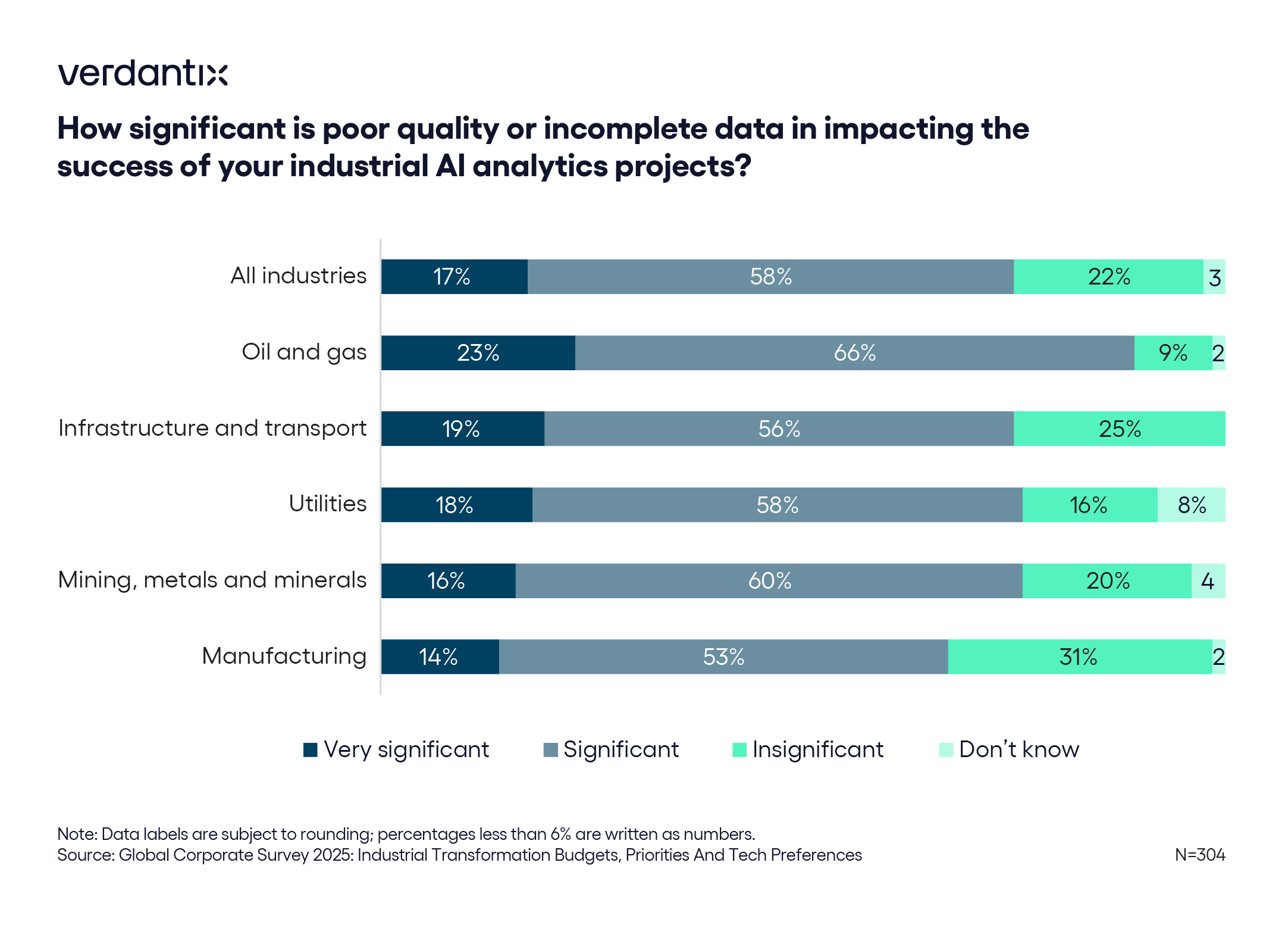

Imagine a refinery halted due to a faulty sensor misreporting overheating. The issue? Bad data. This is one of the hurdles faced by industrial firms looking to implement asset performance management (APM) and artificial intelligence (AI) solutions, as highlighted by the 2025 Verdantix industrial transformation global corporate survey. Around 75% of industry managers said bad or incomplete data significantly hinders the success of their AI analytics projects. Shockingly, this number is considerably higher in some industries: 89% of respondents in the oil and gas sector indicated that it’s a significant barrier.

Without an effective industrial data management (IDM) strategy, predictive maintenance fails, asset optimization suffers and operational efficiency declines. Many organizations deal with outdated systems, disconnected databases and inconsistent naming conventions. Small data discrepancies can derail analytics, inflating maintenance costs and raising the risk of downtime. To ensure reliable asset records and improve analytics confidence, firms must adopt standardized conventions and create data governance frameworks. Incorporating IoT technology can enhance AI predictions with real-time sensor data, enabling better insights and early anomaly detection. Robust AI analytics and data management underpin effective APM by providing the clean, unified data required to power predictive algorithms, enabling more informed maintenance decisions and optimizing overall asset performance.

The Green Quadrant: Industrial Data Management Solutions 2025 benchmark report underscores the need for leading platforms that unify data from legacy and modern systems, providing trustworthy, real-time insights. Advanced data orchestration is crucial for boosting AI performance and improving maintenance insights.

Ultimately, AI analytics and APM software can significantly reduce downtime, enhance predictive insights and lower maintenance costs – but only with reliable data as a foundation. Bad data can derail forecasts, waste resources and erode trust. Investing in IDM solutions to standardize processes, eliminate data silos and automate validation will help organizations achieve the benefits of predictive maintenance and gain a competitive edge. Clean data is essential for any successful AI strategy.

To learn more about leveraging AI and APM through a robust IDM strategy, check out:

- AI And Data Management: Revolutionizing Industrial Transformation In 2025

- Green Quadrant: Industrial Data Management Solutions 2025

- Strategic Focus: Why Industrial Firms Need DataOps Platforms For Asset Management Digitization

About The Author

Robin Sureda-Tasis

Analyst