The Six Questions To Ask Your Prospective APM Software Supplier

When we probed 259 senior executives with operations, maintenance, engineering and process safety responsibilities in the Verdantix Corporate survey about using asset performance management (APM) software across their industrial facilities, we heard that 75% of them either have pilot projects in place or are using APM software in a limited manner at a few sites. Verdantix research forecasts a 5-year 12% CAGR (2020-2025) for the APM software market and expects to see many of these pilot projects expanding as customers begin to witness the technology benefits at their facilities.

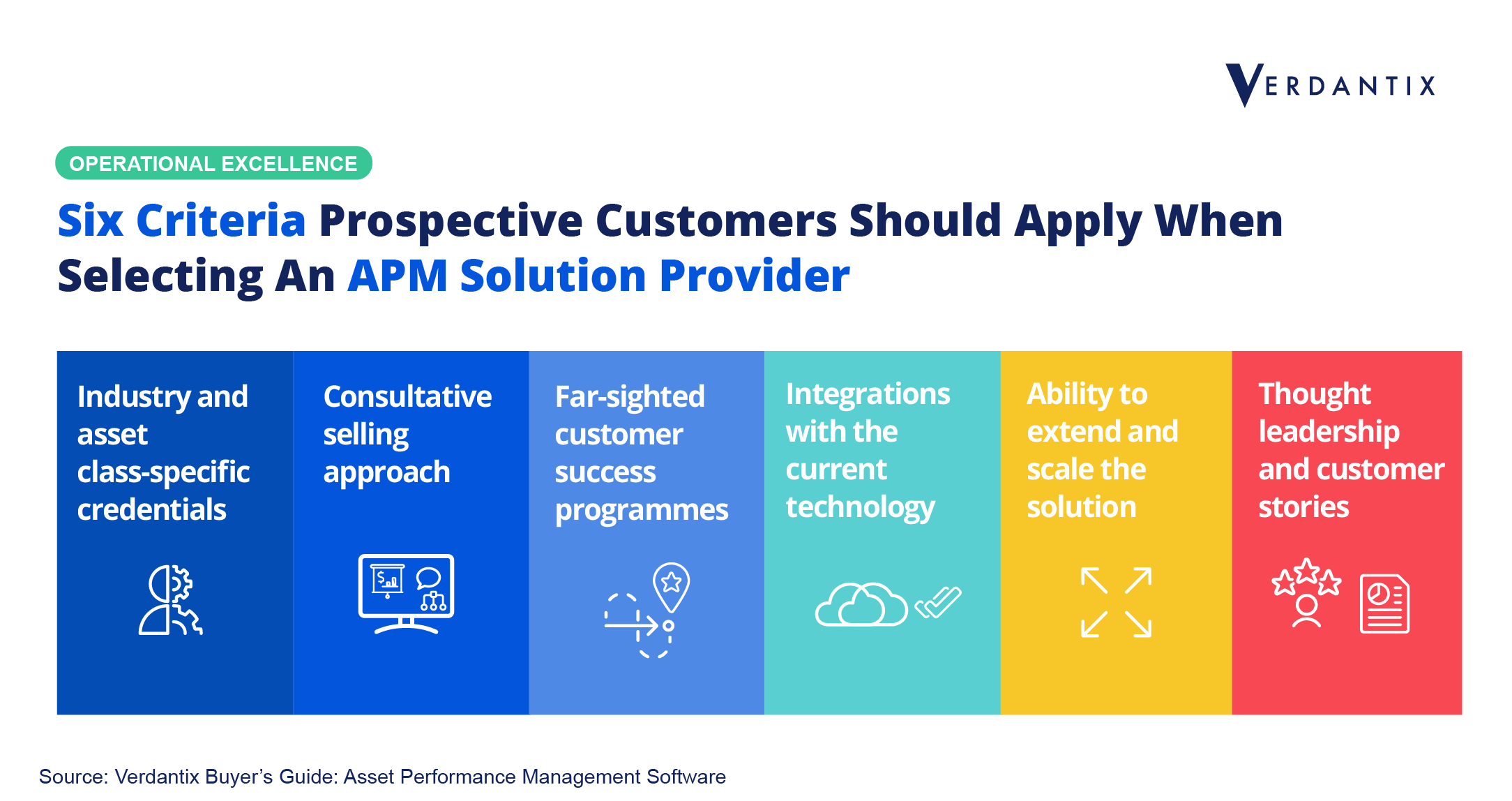

This customer demand has resulted in multiple new entrants in the already crowded and fragmented market – from tech giants AWS and Microsoft to large enterprise asset management (EAM) software vendors IBM, Pragma and SAP – making the software selection process even more complicated. In our recent Buyer’s Guide on APM software, we recommend that prospective customers ask six key questions during the vendor shortlisting process:

Which industries and asset classes do you cater to?

The knowledge and understanding of best practices in each industry will be key to accelerate deployment but also multiply the value derived from APM software and should be a key shortlisting criterion. In the Verdantix Green Quadrant APM benchmark we found that DNV was a frontrunner in its O&G midstream expertise, while Hitachi ABB Power Grids exhibited deep knowledge as well as customer base for power T&D applications.

What are the benefits and how quick is the ROI?

The supplier should demonstrate a convincing business case with clear ROI specifically for the plant’s needs. Senseye prioritizes quick ROI with its plug-and-play predictive maintenance software and recently launched Senseye ROI Lock with full refund guarantee.

How does your customer success programme look like?

Prospective customers should be looking for a supplier with a consultative selling approach that can expertly support potential issues but also advise on expansions and upgrades. GE Digital’s Industrial Managed Services are designed to sustain continuous customer success after a project’s deployment.

What application connectors do you offer?

In this new decade and with digital twins becoming an intrinsic part of digital transformation, it is imperative that any software that is purchased, can easily connect to the plant’s digital ecosystem. Seeq offers an extensible predictive maintenance platform with open REST APIs that also allow third-party-developed ML-algorithm incorporation.

What is your product strategy and roadmap?

Digital transformation journeys are on-going, so prospective customers should always have a far-sighted view on their digital needs and evaluate if the supplier will be a suitable partner to support the more advanced use cases that may arise. Mobility, wearables, 3D visualization and IoT integrations might seem further away than they really are, so planning ahead is crucial.

How does a successful implementation look like?

Always ask for customer examples, references and case studies specifically for your asset classes and industry to understand what the end-product will look like and what it will offer.

To learn more about the advancements and trends in the APM software market, read the new Buyer’s Guide: Asset Performance Management Software and register for the webinar: 6-Step Method To Shortlist The Best-Fit APM Software Vendors.

About The Author

Victor Voulgaropoulos

Director, Advisory Services