Rising Edge Data Integration Shapes Predictive Maintenance Software Vendor Strategies

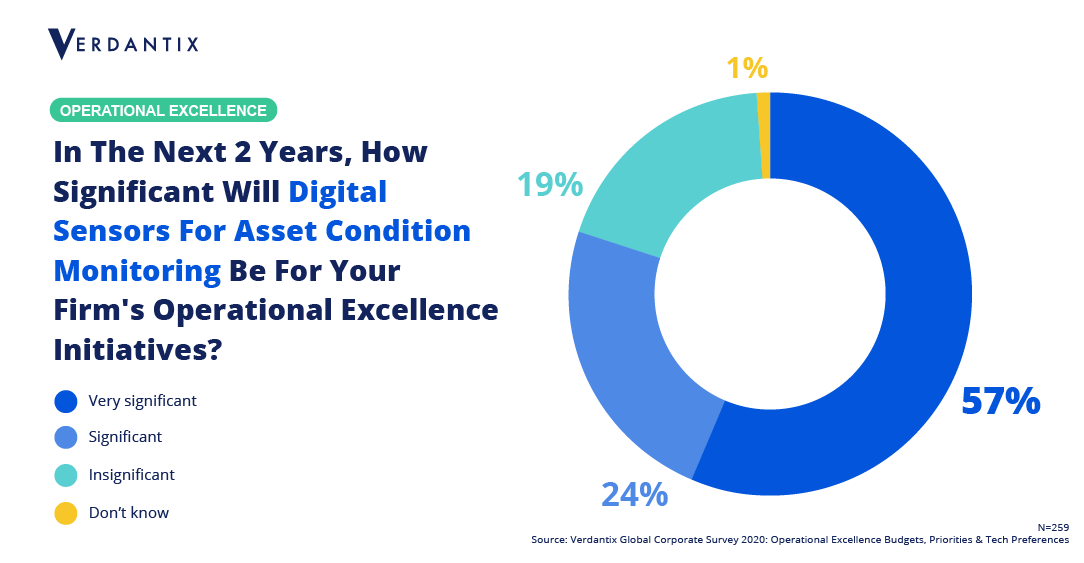

Industrial organizations are recognizing that monitoring of asset health is a key steppingstone of predictive maintenance (PdM) and performance optimization strategies. In the Verdantix 2020 annual global corporate survey of 259 executives in operations, maintenance and engineering roles, 57% mentioned digital sensors for asset condition monitoring as very significant for their firm’s operational excellence initiatives, the highest amongst the 10 innovations considered.

The uptake of sensors is translating to an intrinsically linked demand for asset performance and PdM analytics, as organizations are seeking to leverage the data generated and translate them into actionable insights. This is causing a flurry of acquisitions, partnerships and new entrants in the market, as predictive maintenance software providers seek to exploit these market opportunities. We identify two key strategies that vendors follow.

Firstly, software providers are focusing on improving their positioning by partnering with sensor manufacturers and by bolstering their IoT capabilities. In February 2021, Senseye released Senseye Ready – a partner ecosystem with sensor manufacturers that ensures direct integration of these sensors with Senseye’s PdM software, while in early May, Bentley Systems announced two acquisitions, of sensemetrics and Vista Data Vision, both specialists in IoT and asset health monitoring.

Secondly, software providers are aiming to develop edge functionality to help customers process locally the vast amounts of sensor and IoT data generated. In October 2020, Rockwell Automation, released FactoryTalk Edge Gateway, to aggregate and contextualize OT data at the edge. In December 2020, Amazon Web Services (AWS) solidified its position in the PdM market by releasing Amazon Monitron that tracks the health of rotating equipment by measuring their vibration and temperature. This product was followed by the release of Amazon Lookout for Equipment, which uses data from industrial equipment sensors to autonomously train ML models and offer asset failure predictions locally.

These moves are a testament to the addressable market opportunities currently available for agile end-to-end asset management solution providers. It is expected that more partnerships and M&A will follow to help customers translate raw sensor data to maintenance and performance optimization actions.

For more information on asset management technologies and the software market dynamics, visit the Verdantix Operational Excellence research portal.

About The Author

Victor Voulgaropoulos

Director, Advisory Services