Leveraging Robots And Drones For Automated Visual Inspections

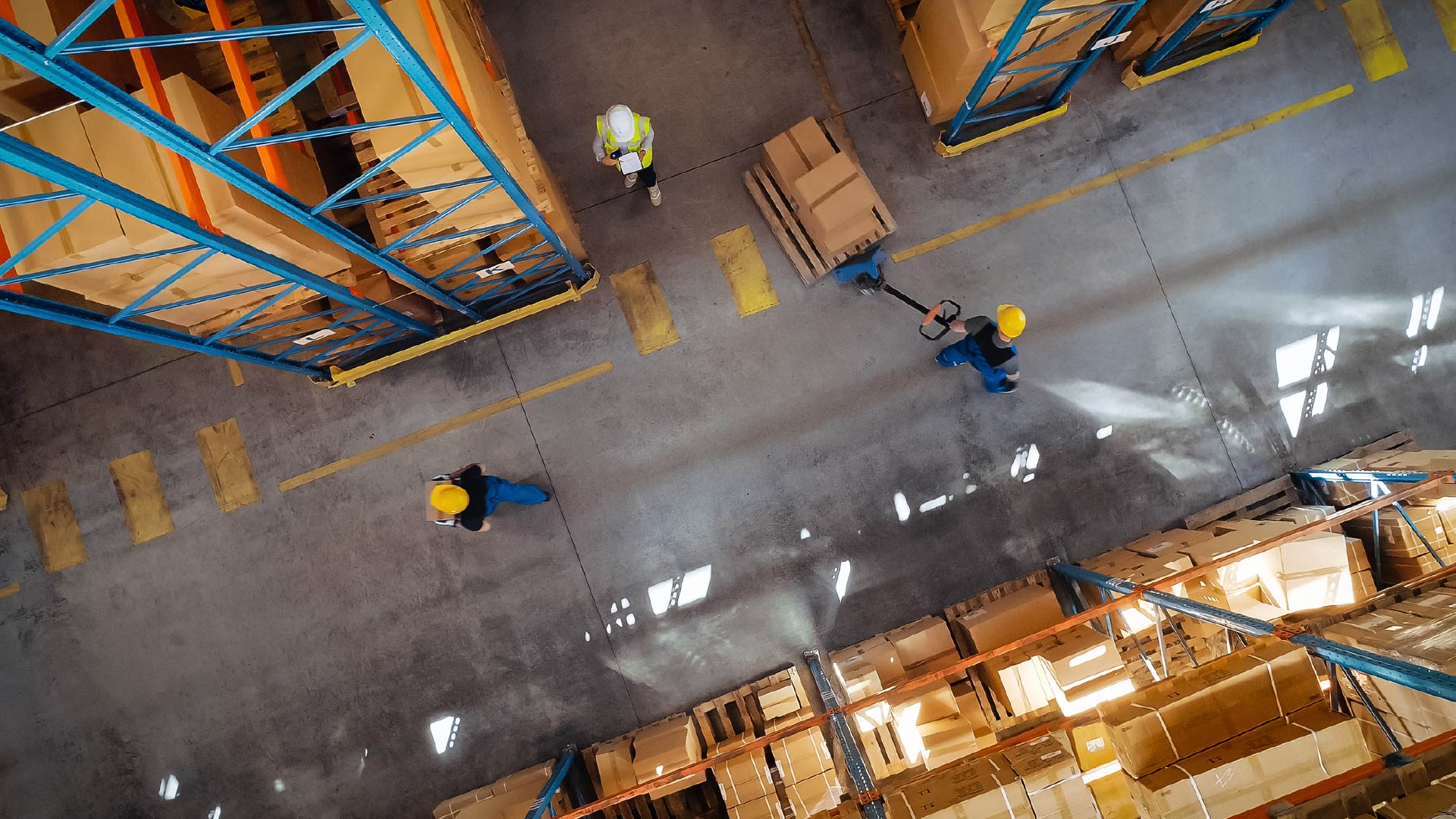

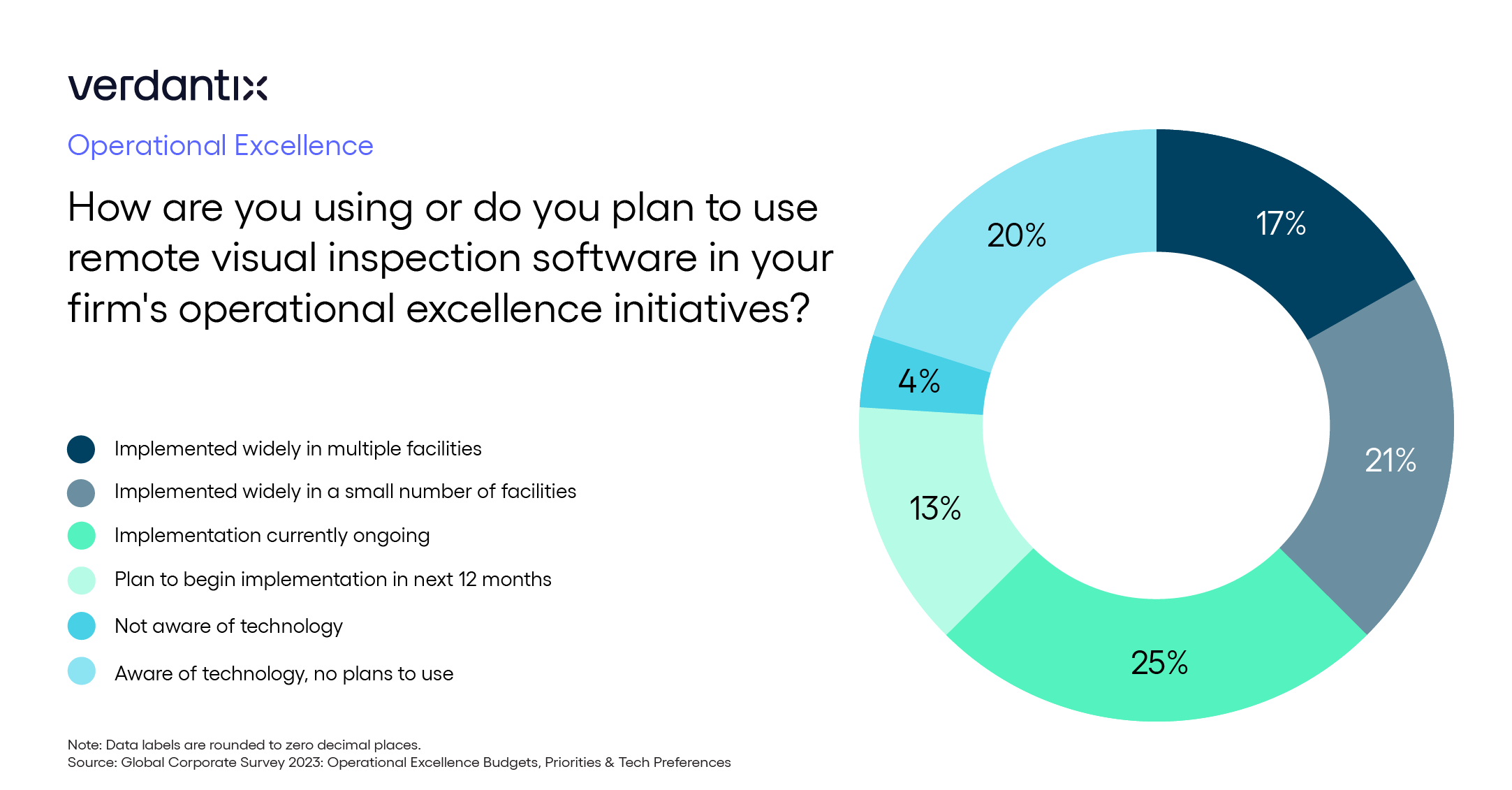

Though dependable, traditional manual inspections are often slow, error-prone, and potentially safety risks. In contrast, computer vision technology presents a compelling alternative, swiftly processing visual data, minimizing human error and ensuring safety in complex settings. Its uses are vast, ranging from defect detection to broader applications like hazard identification, inventory oversight and predictive maintenance. In our latest global corporate survey, 76% of the decision-makers interviewed stated that they are using or plan to use remote visual inspection software. As the merits of this tech become evident, the pivotal challenge becomes data collection. Highlighting this technological shift, in the same survey 70% of respondents reported deploying or plans to deploy robots and drones for their inspection data-gathering needs.

Drones, specifically unmanned aerial vehicles (UAVs), are becoming essential for industrial inspections, particularly in difficult-to-reach locations. Their roles in tasks such as infrastructure monitoring promise enhanced safety and cost savings. Nevertheless, they come with challenges, such as limited battery life. Innovations like DJI's Dock are addressing these issues, providing automated charging and robust all-weather functionality. As their industrial relevance grows, so too will collaborative endeavours. For instance, computer vision specialist Birds.ai has partnered with drone firms Dronematica and Skyability to expand into areas such as solar inspections.

Industrial robots too are revolutionizing visual inspections. From the familiar robotic arms to futuristic models like Boston Dynamics's Spot and Xiaomi's Cyberdog, robotic innovations hint at a new era — perhaps even one of humanoid robots, as suggested by Tesla's recent unveiling and OpenAI's significant backing of 1X Technologies. These robots excel in automating repetitive tasks — like equipment checks and non-destructive testing — amplifying safety, productivity and quality while curbing labour costs. Operating on predefined routes, these robots make inspections systematic, championing remote management and predictive maintenance. A collaboration worth noting involves Boston Dynamics and Vinsa, wherein Vinsa's Intelligence Models are integrated into the Spot robot, optimizing tasks such as facility assessments and anomaly detection.

However, it’s not just drones and robots that are shaping the future of visual inspections, but also devices such as autonomous underwater vehicles (AUVs), satellites, and advanced cameras. When combined with computer vision, these tools are paving the way for a more accurate, efficient and safe operational environment.

For more information on visual inspection technologies, visit the Verdantix Operational Excellence research website.

About The Author

Henry Kirkman

Industry Analyst