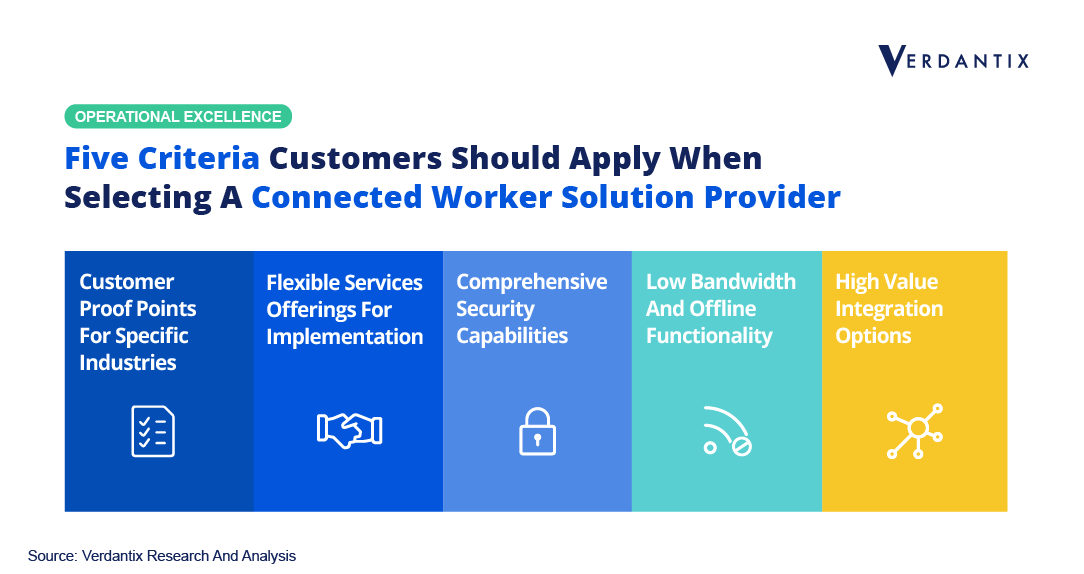

Five Criteria Customers Should Apply When Selecting A Connected Worker Solution Provider

Joe Lamming

Connected worker solutions help to bridge the gap between assets and front-line workers who operate, maintain and repair them. Firms should consider the five criteria below when assessing connected worker solution providers:

1. Customer proof points for specific industries.

While applications of connected worker (CW) solutions are usually industry agnostic, each industry – and buyer – will find alignment with a subset of solution providers. Prospective buyers should thoroughly review industry-relevant case studies to ensure a software solution will deliver return on investment. For example, Blackline Safety has a strong customer base with water utilities, while Damstra Technology has an established presence with customers in the marine sector and Parsable in food and beverage and FMCG sectors.

2. Services for smooth implementation and change management

Time required to deploy an effective CW solution depends on the specific application. Mobile apps for work instructions may take just a few weeks to implement, but with wearables and associated infrastructure, acceptable time-to-value may depend on vendor and partner post-sales support – meaning prospective buyers must push vendors to provide clear timelines. SightCall offers well-established solutions via iOS and Android apps, while TeamViewer deliver services for end-to-end implementation based on customer requirements.

3. Comprehensive security capabilities

High-profile cybersecurity issues and data breaches are becoming more prevalent as the industrial world embraces digitisation and IoT, either from improper deployment on the buyer side or poor software design by vendors. In sensitive industries like aerospace and defence, security is highly prioritised – but when considering CW solutions, prospective buyers must also consider workforce willingness and whether sensitive employee data such as those generated through location and vital signs monitoring are given robust privacy protections and usage oversight. To tackle security concerns, Atheer and AMA offer encrypted communication.

4. Low bandwidth and offline functionality

Workers in industrial facilities or remote jobsites will frequently encounter intermittent or non-existent internet connectivity. Buyers should choose CW solutions with robust offline functionality – such as downloadable work forms – and stable upload queuing for when connection is re-established, along with dynamic bandwidth management for remote assistance calls. Damstra combines cellular, Bluetooth and satellite communication (via vehicle router) to maintain connectivity in remote areas, while Librestream can deliver video calls using 30kbps bandwidth.

5. High value integration options.

CW solutions must integrate into existing IoT and software systems to minimise time-to-value and maximise worker adoption. Buyers seeking both hardware and software CW solutions should look for vendors with established partnerships to maximise functionality of the deployment – alongside integrations with existing EAM and FSM systems. Guardhat partners with more than 30 firms, providing integrations with a variety of hardware and industrial software systems, while PTC offers deep integrations via REST APIs to enterprise data lakes and historians.

To learn more about connected worker solutions, read our latest Buyer’s Guide: Connected Worker Solutions report.

About The Author

Joe Lamming

Senior Analyst