AI Plays A Central Role In Bolstering The Three Pillars Of Sustainability In Manufacturing

The concept of sustainability can be analysed far beyond the lens of environmental conservation. Today, sustainability embodies a comprehensive strategy that not only addresses ecological concerns but also prioritizes operational safety, efficiency, and the overarching health of both people and processes. This broader interpretation of sustainability is vital for fostering resilience, especially in industrial firms – ensuring they can withstand and adapt to an ever-changing global landscape. AI is acting as a catalyst for this by:

- Improving operational efficiency.

At the heart of sustainable manufacturing lies the drive for increased operational efficiencies. This entails optimizing plant performance and production to reduce waste and conserve energy. For instance, Augury’s Process Health solution allowed Italian food firm Barilla to identify and proactively address causes of production inefficiency, resulting in a 37% reduction in waste. On a similar note, the New Belgium Brewing Company addressed its frequent unscheduled shutdowns by implementing AVEVA’s manufacturing execution system. As a result, not only did the shutdowns cease, but the organization also succeeded in expanding its packaging capacity to 1.3 million barrels annually, while driving costs down.

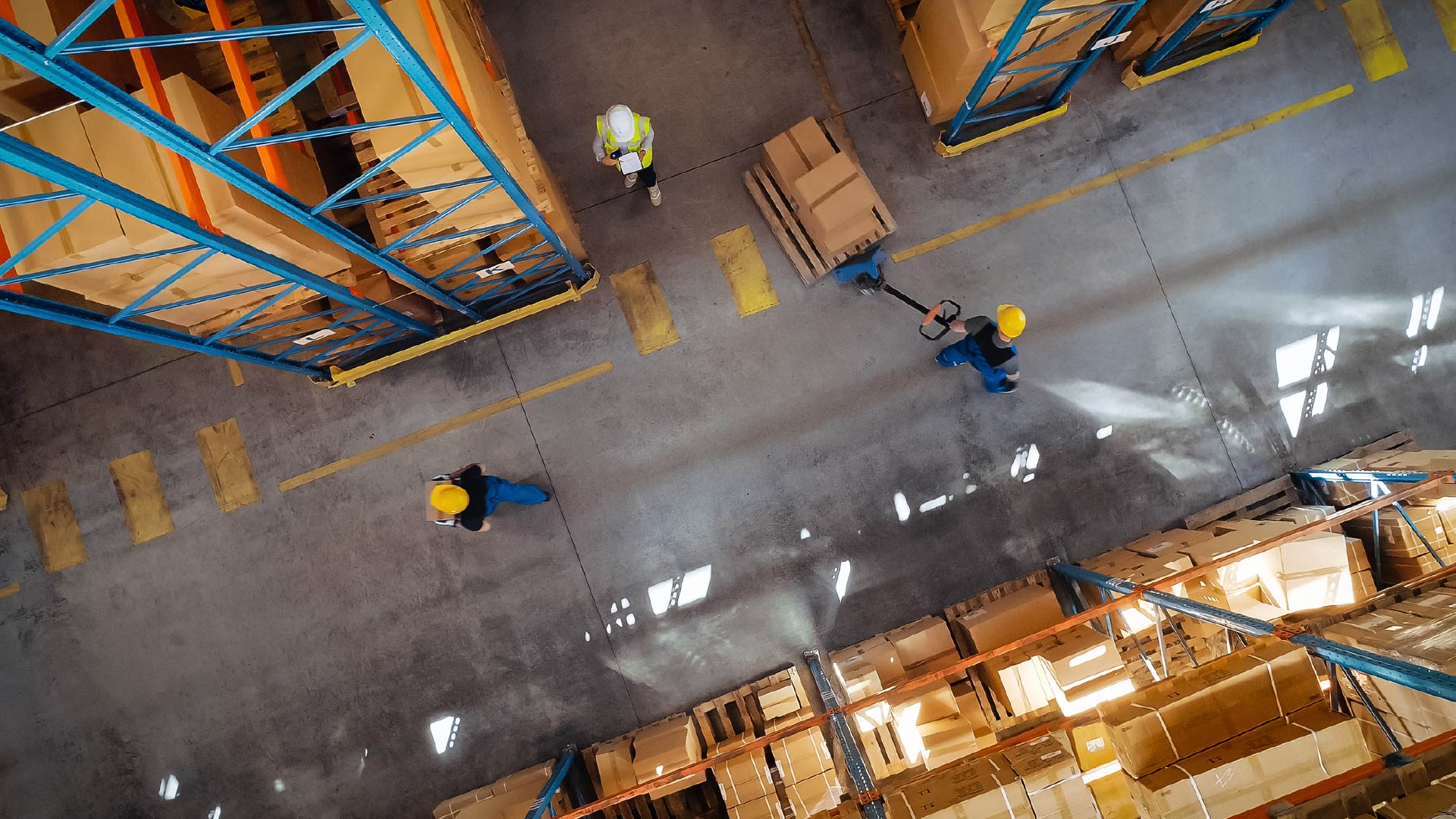

- Ensuring safe operations.

In the 2022 Verdantix operational excellence global corporate survey, 53% of the 301 executives surveyed placed safe operations at the top of their priority list. Deploying technologies to support a safer and healthier workplace leads to enhanced productivity as well as better employee retention and satisfaction. Voxel’s computer vision solution, allows for the detection of risks and hazards such as inappropriate use of personal protective equipment (PPE), spillages and dangerous areas. Upon implementation of Voxel’s product, Americold saw a 90% reduction in unsafe flagged behaviours and 77% reduction in work-related injuries.

- Achieving environmental stewardship.

Reducing environmental impact is a fundamental component of sustainability and a current priority for manufacturers. In the Verdantix 2023 operational excellence global corporate survey, 62% of respondents stated plans for double- or single-digit increases in spend on the decarbonization of their plant operations. AI-powered tools play a pivotal role in optimizing energy as well as resource usage. The Empire State Building in New York leverages WINT AI’s solution to optimize its water consumption, saving 7.5 million gallons of water and approximately $100,000 per year.

While the use of AI solutions in manufacturing is becoming prevalent, it is essential to stress the importance of accurate data for AI and ML to be successful and provide accurate insights. Therefore, if deploying AI-based solutions is of interest, manufacturers should firstly ensure a strong data engineering and management structure.

For more, read the full report – Market Insight: 10 Applications Of AI For Sustainable Manufacturing.

About The Author

Lucas Sala

Analyst