Shell Plans To Further Its Digital Transformation Initiative With The Adoption Of Kongsberg’s Digital Twin Software Across Its Global Portfolio Of Assets And Projects

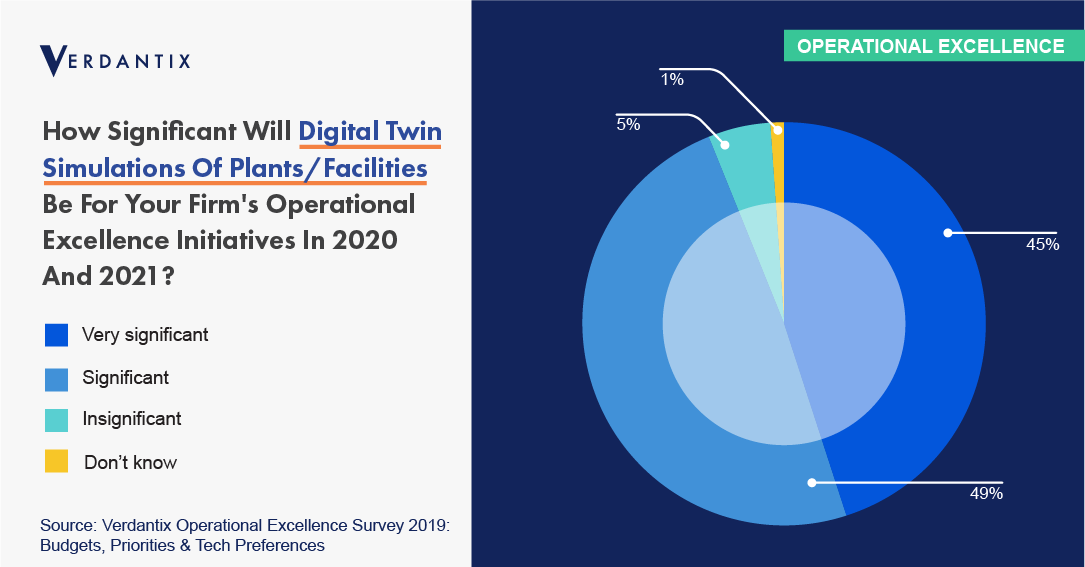

The inexorable rise of digital twin software for industrial facilities took centre stage in the 2019 Verdantix survey of executives in operations, maintenance, engineering and process safety roles, topping the list of digital innovations for operational excellence. Specifically, 94% of the 284 respondents stated that digital twins will be ‘very significant’ or ‘significant’ for their firm's operational excellence initiatives in 2020 and 2021.

Among the Industry 4.0 protagonists, Shell is again in the spotlight, as it seeks to further accelerate its digital transformation initiatives by implementing digital twin solutions across its global portfolio of assets and capital projects. Shell has signed an enterprise framework agreement with Kongsberg Digital, a Kongsberg subsidiary, for the deployment of Kongsberg’s Kognitwin Energy, a cloud-based Software-as-a-Service (SaaS) digital twin solution, within Shell’s upstream, Liquified Natural Gas (LNG), and downstream business lines. Kognitwin Energy utilizes high-fidelity physics-based models, and machine-learning algorithms, to simulate the actual operation of a plant or asset, and generates synthetic data where measurements are not available.

Shell’s project is part of its multi-front digital twin adoption strategy. It follows the successful deployment of digital twin technology from Akselos at its Bonga Floating Production Storage and Offloading (FPSO) vessel in Nigeria, which weighs more than 300,000 tonnes and was the largest such asset to have been digitally twinned. In August 2020, Shell announced its plan to pilot digital twin technology at its integrated refinery and chemicals manufacturing site in Singapore. This four-year pilot project will witness Shell consolidate information from over 20 different technology platforms and have all critical field operations performed through tablets.

Digital twin technology is expected to play a major part in the operational excellence strategies of firms in the near future, and Shell’s initiatives, across a wide range of assets and plants, sets a strong foundation proving the technology’s improved ROI as well as time-to-value. For the laggards that have still to invest in digital twin software for industrial facilities, or for innovators that want to get a granular understanding of its capabilities and explore more use cases, Verdantix’s Buyer’s Guide offers a high-level assessment of 26 prominent vendors based on seven core capabilities and across 15 different asset classes.

About The Author

Victor Voulgaropoulos

Director, Advisory Services