Rising Awareness Helps Industrial Digital Twins Cross The Chasm From Early Adopters To Early Majority

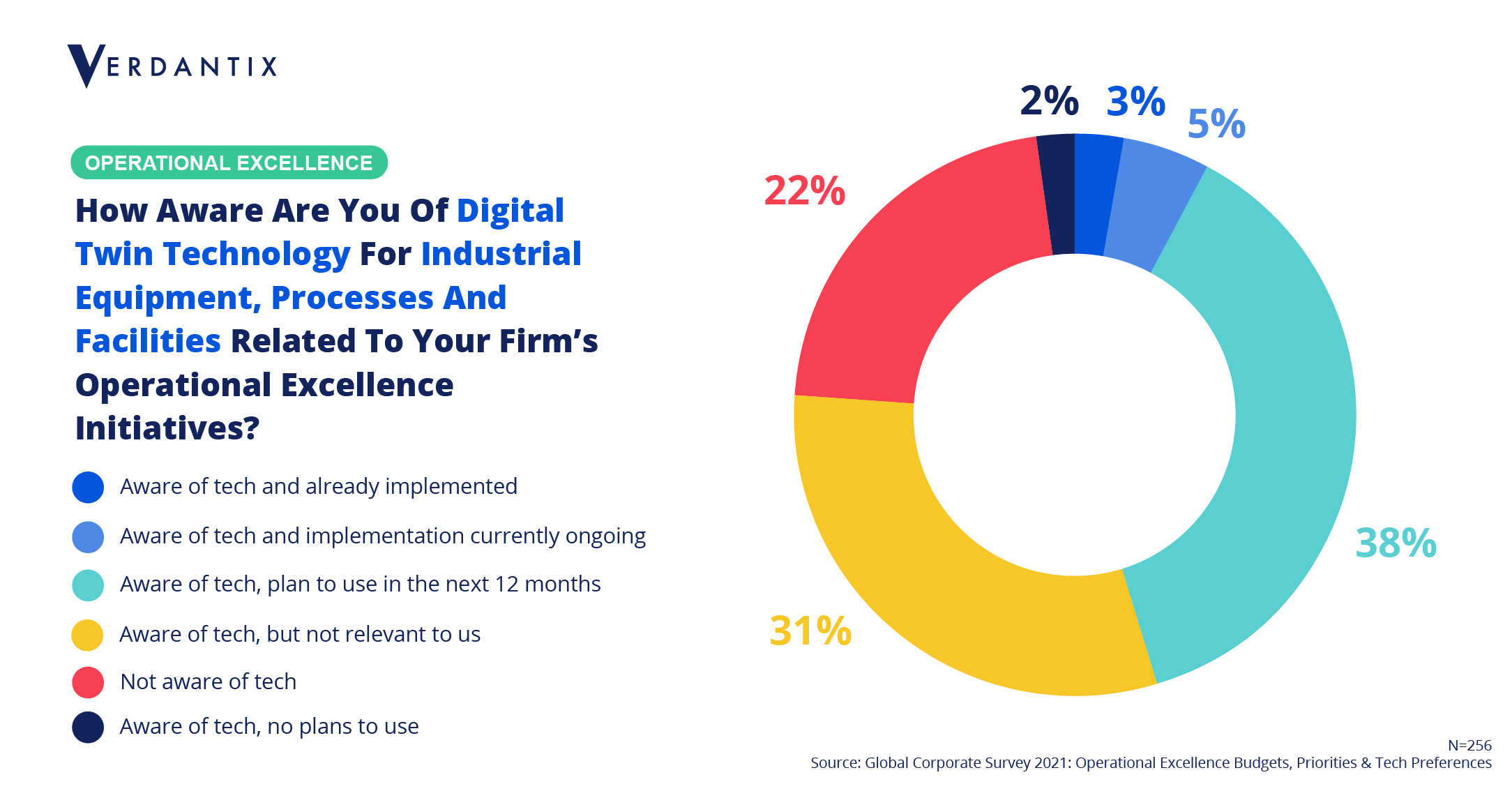

The Verdantix 2021 global survey of 256 executives in operations, maintenance, engineering and process safety roles has shown there to be a high degree of awareness of digital twin technology. 46% of the respondents are aware of digital twins and mentioned that they had either implemented or will be implementing digital twins within the next 12 months across their organization. This growth in implementation has been a long time coming and reflective of the trends seen over the past two years – the majority of operations executives in our 2019 and 2020 surveys have consistently highlighted digital twin simulations of assets and industrial facilities as either ‘very significant’ or significant for their firm’s operational excellence initiatives. Furthermore, our research predicts that the industrial digital twins market will grow from $5.1 billion in 2021 to $13.9 billion in 2026.

What is driving this growth? The idea of implementing digital twin solutions have been investigated for many years, but with the rapid growth of computing power, data visualization, interoperability, simulation and modelling capabilities and the growing global sustainability pressures; organizations are finding digital twins to be more and more accessible and essential for achieving their business objectives.

Recently Chevron announced that they are planning to install sensors on critical equipment such as heat exchangers and compressors to create a real-time digital twin predictive maintenance system. Portuguese Refiner, Galp Energia announced that they have implemented a digital twin on their refinery for energy management; with aim to improve overall operation, reduce energy intensity and GHG emissions.

While digital twin implementations are on the rise, the technology is still nascent. Hence, customers are trying to glean best practice strategies to succeed with their digital twin projects. Our research recommends customers take a holistic approach that spans five core aspects – people, data, hardware, connectivity and security.

To learn more and stay up to date with digital twin trends and forecast, please read the following reports: Market Size And Forecast: Digital Twins For Industrial Facilities 2021-2026 (Global), Best Practices Implementing Industrial Digital Twins.

About The Author

Kiran Darmasseelane

Senior Manager