Strategic Focus: Improving Safety With Robotics And Automation

Rain Chiang

17 Nov, 2022

Access this research

Access all EHS Specialist Software content with a strategic subscription or buy this single report

Need help or have a question about this report? Contact us for assistance

Executive Summary

Robots have automated repetitive and dangerous industrial tasks since their initial deployment in the automotive manufacturing industry in the 1960s. In 2021, the International Federation of Robotics reported that industrial robot installations had been increasing year on year by 16% on average since 2016. The trend to digitize operations has been driven in part by the COVID-19 pandemic, which has changed how firms decide to deploy human capital. Modern advancements in environmental sensors, machine vision and advanced mechanics have expanded the applicability of robots to several high-risk functions. EHS executives should recognise the increasing complexity of tasks industrial robots can automate and the implications for worker safety and plant efficiency. As a result, firms should take a holistic approach to investment in robotics and automation that accounts for these tangible and intrinsic benefits. This report outlines the key safety benefits and implementation considerations when automating human-led tasks with industrial robots. Readers can identify applicable use cases from the examples provided to help inform the implementation of robotics and automation for safety.

Robotics And Automation Create Compelling Safety And Efficiency Considerations For Investment

Industrial Robots Fit Into Three Broad Categories

The Elimination Of Human Exposure To Workplace Hazards Creates Far-Reaching Safety Benefits

Firms In High-Risk Industries Use Robotics And Automation To Perform Dangerous Tasks

Automated Industrial Robots Present Unique Implementation Considerations

Industrial Robots Fit Into Three Broad Categories

The Elimination Of Human Exposure To Workplace Hazards Creates Far-Reaching Safety Benefits

Firms In High-Risk Industries Use Robotics And Automation To Perform Dangerous Tasks

Automated Industrial Robots Present Unique Implementation Considerations

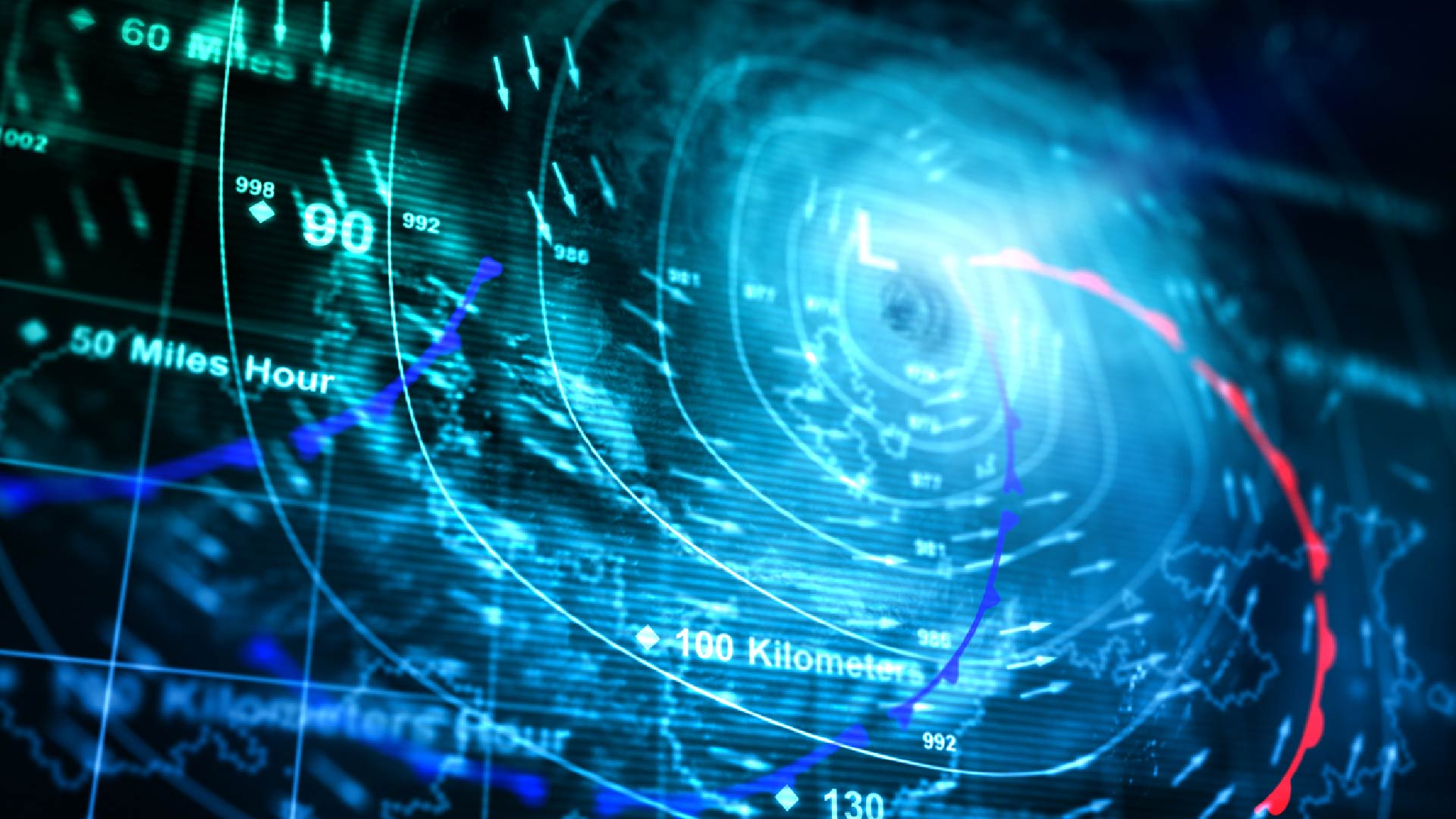

Figure 1. An Illustration Of Industrial Robots In A Highly Automated Warehouse

Figure 2. Case Studies Of Robotics-Enabled, Safety-Focused Processes By Industry

Figure 2. Case Studies Of Robotics-Enabled, Safety-Focused Processes By Industry

About the Authors

Rain Chiang

Industry Analyst

Rain is an Industry Analyst in the Verdantix EHSQ practice. His current research agenda focuses on the intersection between EHSQ and ESG priorities. Prior to joining Verd...

Bill Pennington

VP Research

Bill is VP Research at Verdantix, where he leads analysis on the evolving and interconnected landscapes of EHS, quality, AI and enterprise risk management. His research helps ...

View Profile